Hyundai Motor Group’s E-GMP offers many unprecedented ways to experience the automobile, both functionally and emotionally. What aspects of its technology allow such novel user experiences? We interviewed Vice President Choi WooSuk, Head of Electrification Development Center, for details on the subject.

The E-GMP(Electric-Global Modular Platform), Hyundai Motor Group’s first platform dedicated to Battery-Electric Vehicles (BEV), is designed with several innovative features. Some notable ones are a multi-charging system that supports both 800V high-speed charging and 400V fast-charging, a generous driving range of 500 km or more on an 18-minute charge, and the V2L(Vehicle to Load) feature, which allows external devices to use the vehicle battery as a source of power. The common ground of these features is that they all dramatically improve the convenience and utility of BEVs, providing unprecedented user experiences for their consumers.

These distinguishing features of the E-GMP were born in Hyundai/Kia’s Electrification Development Center. The center is responsible for design and development of core EV parts like the motor, inverter, converter, and battery; in essence it works to build the next-gen systems and technologies that will give the group an edge in the global vehicle electrification market. The head of the center, Vice President Choi WooSuk, joined us in an interview to discuss the E-GMP’s many innovative features.

Q. How does the *PE(Power Electric) System on the E-GMP distinguish itself from Hyundai Motor Group’s existing EVs based on internal combustion engine vehicle (ICEV) platforms? Or from that of competitor technologies?

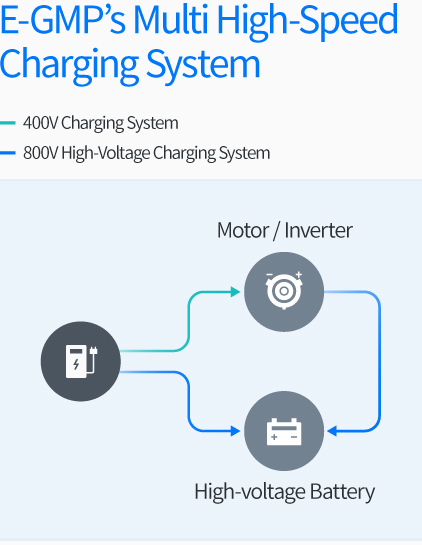

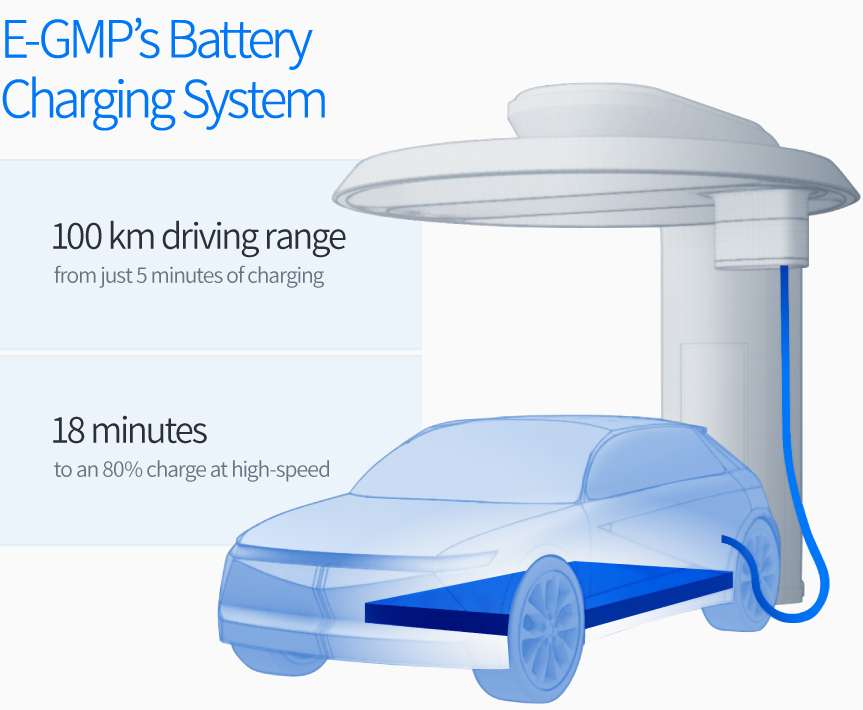

Hyundai Motor Group’s PE System is distinguished by its ‘multi high-speed charging system,’ the first of its kind in the world developed by us. ‘Multi high-speed charging’ means that the system is compatible with both 800V high-speed charging and mainstream 400V fast-charging without needing a special adapter. It maximizes drivers’ convenience by freeing them from having to check stations’ charging compatibilities every time. The high-voltage 800V charging system is set as default in the E-GMP, which dramatically reduces the time needed for charging. High-speed charging can charge the battery to 80% within just 18 minutes, and one full charge offers a driving range of over 500 km. If you’re pressed for time, charge just for five minutes—that will still get you a good range of 100 km.

*PE (Power Electric) system, roughly equivalent to ICEV powertrains, comprises the motor (for power generation), EV transmission (reducer), inverter (energy conversion), and battery (energy storage).

Granted, even before this innovation, BEVs equipped with 800V high-voltage charging systems could technically use 400V charging infrastructures. However, doing so required a separate part called the Onboard Charger (OBC). Think of a voltage transformer that you would need to use 110V appliances in a 220V electric environment. That’s what OBC essentially does, and up to today, it was normal for automakers to offer it as an option for consumers at an additional cost.

The E-GMP’s multi high-speed charging system takes care of that inconvenience. It uses the vehicle’s motor and inverter to convert the 400V current coming from the outside charger into 800V so that it can be stored in the battery.

Q. What led you to develop the 800V high-voltage charging system?

It started from a marketability survey in which we found that reducing the time needed for charging was one of the biggest EV consumer demands. Charging a BEV with a 400V charging system with a 50kW fast-charger takes about an hour to charge to 80%. For consumers who are used to fueling gas in a minute or two, that’s way too long and inconvenient. And the trend has been to equip BEVs with higher-capacity batteries to secure longer driving ranges, which made the charging duration even longer. One way to resolve this issue was by adopting the 800V high-voltage charging system, which is 3 times faster than the existing 400V ones.

Q. EVs based on ICEV platforms are quite practical and efficient themselves. What makes the PE System on the E-GMP even better than them?

As you say, EVs built on ICEV platforms are quite efficient as is. But they do have some concrete limits, stemming from the fact they are developed on an ICEV platform that was not designed for them. Crucial BEV parts like motors and batteries are made to suit that platform, which produces the irony of not being able to use EV-dedicated parts to build EVs. So they have to use generic parts they share with other electrification categories like hybrids and plug-in hybrids.

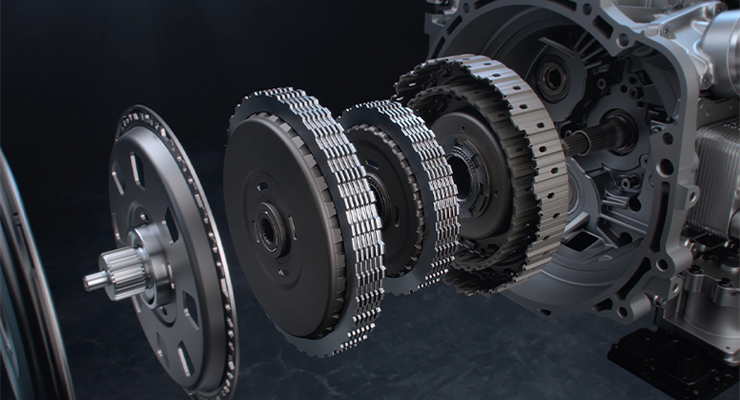

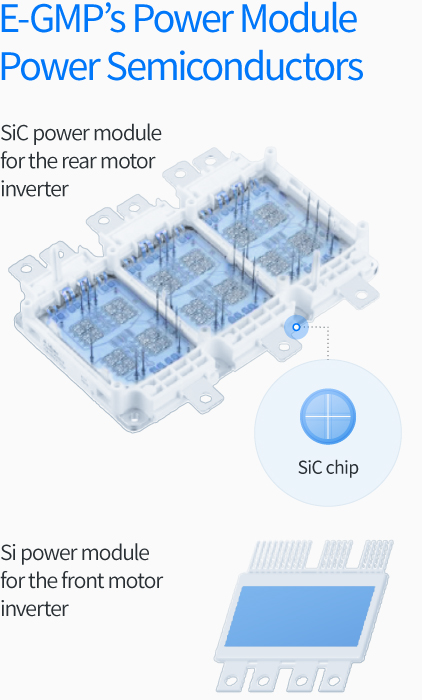

On the contrary, from the first stage of design, the E-GMP has only used the EV-dedicated PE System and other dedicated parts. As a result, the motor, inverter, and transmission were able to be integrated to make the PE system more compact and lightweight. In addition, the power module, which is a core part responsible for converting the electrical energy in the motor, got a next-gen power semiconductor with Silicon Carbide (SiC), leading to about a 5% increase in the driving range. In terms of the energy stored on the battery, that increase in range is equivalent to one provided by 1.5 battery modules—the omission of which can obviously make the vehicle lighter.

Changing the material for the power semiconductor is a great example of the advantage provided by the E-GMP’s EV-dedicated nature. When designing inverters, whose function is to convert direct current (DC) to alternating current (AC), we can choose to use SiC or Silicon (Si) as the material for the power semiconductor. Normally, Silicon is used because it’s cheaper. But SiC comes with one advantage that Si cannot parallel: its ability to work in high-voltage, high-current, and high-temperature settings. So for the 800V high-voltage system that the E-GMP is supposed to work with, it made more sense to select SiC to increase the inverter efficiency. So the rear motor, which is the main motor of the E-GMP, got a SiC power module, whereas the front motor got our internally-developed Si power module. That’s how the E-GMP provides an optimal solution on both ends of cost and efficiency.

Q. Can battery packs for large sedans or SUVs be composed of standardized battery modules? What is the technologically feasible limit of battery pack composition?

There are no technological limits. Hyundai Motor Group is expanding E-GMP’s application to a diverse range of segments including large BEV sedans and SUVs, and their battery packs too can be built flexibly with the standardized modules. In preparation for that development, we’re developing large-capacity batteries of 100kWh or more. The final choice of battery capacity and driving range will be optimized to the circumstances then, including market demand, safety concerns, and supply chain capacity.

Q. The Hyundai Ioniq 5 and the Kia CV, both scheduled for release in 2021, are BEVs based on the E-GMP. What sets them apart from existing BEVs in the market?

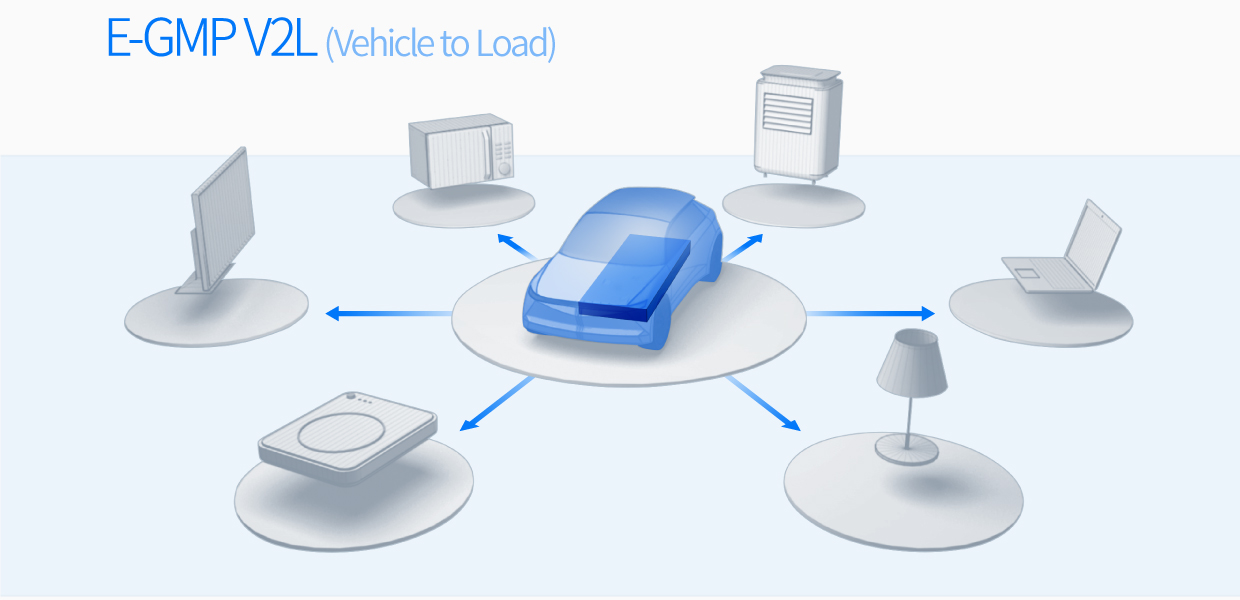

We’ve already talked about the E-GMP’s efficiency and driving range increase, as well as the reduction of charging time from 800V high-speed charging. Of course, there are more advantages to the E-GMP than just that. One exemplary advantage is the V2L(Vehicle to Load) technology, which is again made possible by using EV-dedicated parts.

V2L technology makes it possible to supply external devices with the electricity stored in the vehicle battery. It basically makes the BEV battery a gigantic portable power bank. This should allow the Hyundai Ioniq 5 and the Kia CV to really become “utility” vehicles in a way that existing EVs cannot match. For example, you can just grab any household electric appliance (110V/220V) and use it outdoors by using the electricity in the battery. At a time when car camping and sleeping in your car are becoming a fad, V2L can be a difference-maker.

Granted, you can do the same thing with some of the existing BEVs as long as you have a 220V inverter. But V2L on the E-GMP can support not just small camping equipment but even household appliances requiring a large amount of power, which opens the door to new outdoor experiences. Not just that, you can even charge other BEVs with V2L. Using it, you can even help an out-of-battery BEV on the roadside waiting for a rescue.

Q. Motor technology in a BEV appears to have reached a certain threshold, but battery technology is developing and evolving as we speak. What are some difficulties with BEV battery R&D?

As you say, despite some small differences across manufacturers, EV motors are now generally capable and have reached that shared threshold of excellence. As for us, we have reached 93% in motor system efficiency thanks to our R&D efforts, including the application of the aforementioned SiC power semiconductors on the inverter.

Battery technology has grown faster than expected, and that has led to big increases in BEV driving ranges. But because BEV batteries take a long time to charge, people have come to expect generously long driving ranges. This shift in consumer attitude means that a new battery system built on technological innovation is becoming crucial.

Q. The importance of the battery in a BEV has led many car manufacturers to make their own batteries. Is Hyundai Motor Group joining this trend?

The battery is the single most important determinant of a BEV’s weight and driving range, and one of the important determinants of vehicle pricing. If you want to expand the BEV market, you have to lower the cost of battery production; if you want to expand your BEV lineups, you need a steady and stable supply of batteries. Those are the reasons why many manufacturers have begun making their own batteries.

Hyundai Motor Group, too, is investing in next-gen battery technologies like solid-state batteries. Unlike the existing lithium-ion batteries, whose electrolytes (the medium that allows the flow of electrical charge) are in the liquid state, solid-state batteries come with solid-state electrolytes. Thanks to this difference, all-solid-state batteries are structurally sturdier and more stable, able to maintain their form even when the electrolytes are damaged. They also offer a higher energy density, which is one of the reasons why they are being highlighted as the next-gen battery solution for BEVs. We believe our efforts in battery technology will continue to produce innovations that offer our consumers longer driving ranges and convenience in charging.

Q. Considering the circumstances, including technological advancements and the fall in battery prices, when will the BEV market share surpass that of ICEVs?

Looking at the trend of BEV development over the years, I would say that both the driving range and charging time have come close to the point where consumers will be generally satisfied. Continuous advancements in battery cell materials have led to a steady fall in battery prices. Everything is pointing to a consistent increase in the market share of BEVs.

But, in order for BEVs to surpass ICEVs, they will need to offer functional and sentimental values that are not easily found in the latter. The V2L feature we talked about is a good example. Other convenience features like wireless charging and autonomous driving will follow to add further unique value to BEVs. Bloomberg New Energy Finance (BNEF) analyzed last year that 57% of all global vehicles sold in 2040 will be EVs. I also think that’s around the time that BEVs will surpass ICEVs in the market.

Q. ICEVs have had a hundred years to gradually develop, whereas EVs have developed rapidly in only a few decades. What accounts for the difference? Where will the EV’s rapid pace of development take us next?

The car manufacturers that are now leading vehicle electrification have long prepared for this paradigm shift in the industry by investing generously in R&D. Hyundai Motor Group started developing EVs roughly thirty years ago, so the E-GMP was not made overnight; it too is the fruition of years’ worth of accumulated R&D.

But recently, the rising public attention to sustainability and carbon footprint concerns, as well as increasingly strict environmental regulations in most major countries, have sped up EV development greatly. Now, charging infrastructure has been established enough to kick-start a virtuous cycle of demand and supply, which prompts the need for accelerated technological development. The resulting competition in core BEV parts like motors and batteries is lifting the industry to unprecedented technological heights. In the future, BEVs will not simply supplant ICEVs but create new demands where none existed—like unmanned delivery vehicles or Urban Air Mobility (UAM).

Q. Will the advent of high-quality EVs based on the E-GMP influence the development of future mobility technologies like autonomous cars and connected cars?

Realizing autonomous and connected cars entails a need for more precise means to control the vehicle. The amount of data to be processed will skyrocket, which will require the controllers to be highly powerful, and consume that much more electricity.

The motor system on the E-GMP is already highly efficient. Its battery system can be tailored to meet the range and energy needs of every model, including the needs for large-capacity batteries. What this means is that the E-GMP can accommodate technologies that consume a lot of energy in ways that existing platforms can’t. In the future, you will likely see autonomous vehicles, and a variety of other future mobility options, calling the E-GMP their platform.