Electric cars are known to be safer than cars with internal combustion engines under more strict safety regulations.

EV batteries undergo a wide array of safety testing and certification before being put into vehicles. Here are multiple safety strategies from building safe batteries to preventing damages from a power outage.

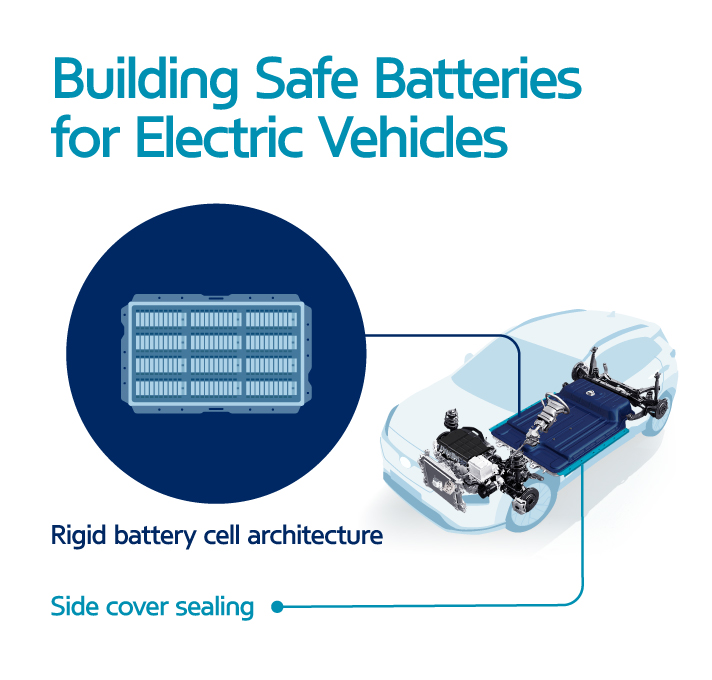

EV batteries are designed to withstand an external shock. This is especially important since the damage on batteries can be more severe in side-impact collisions than in front or rear-impact collisions in which the vehicle body can absorb the impact. They are built with ceramic-coated separators to improve strength, and instead of using a conventional permeable membrane, pouch-type lithium batteries with excellent heat-dissipation properties(battery compartments wrapped in aluminum foil) are used to protect the battery from external heat. Plus, side cover sealing has an additional impact absorber.

*Battery separators for electric vehicles: A separator is a permeable membrane placed between a battery's anode and cathode. The main function of a separator is to keep the two electrodes apart to prevent electrical short circuits while also allowing the transport of ionic charge carriers that are needed to close the circuit during the passage of current in an electrochemical cell. Membranes are synthesized by two kinds of processes - dry and wet. The wet process is widely used because of its simple procedures and uniform pore sizes. On the other hand, the batteries for EVs are built with ceramic-coated separators to improve strength.

EV batteries undergo a wide array of safety testing and certification before being put into EVs, with not only safety designs, but also crash safety (rear impact for testing battery explosion safety), water tightness (for water resistance), submersion (saltwater immersion testing), and combustion (tests containing direct fire exposure).

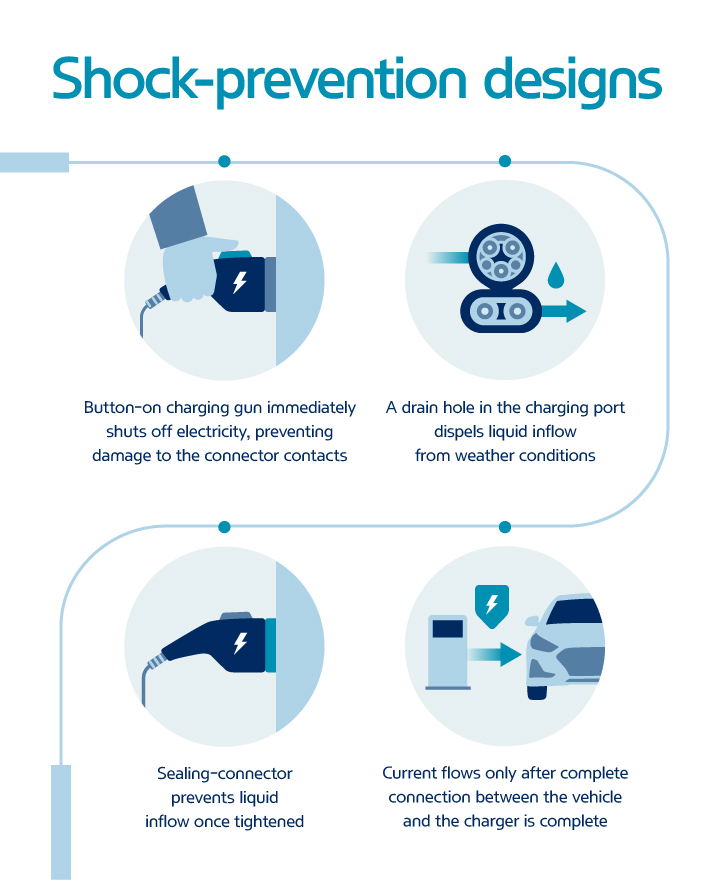

Just like home appliances, electric vehicles use electricity to function. When you are using regular home appliances, a short circuit can cause a power outage. EV makers, on the other hand, designed their products under multiple safety structures to prevent such situations.

Vehicle Cooperative Control - the battery is a power supply that is linked to electric motors and various electrical components, which can affect the battery if high voltage components fail. Fail-safe features and integrated into the design to prevent such failures from impacting the battery.

Active Protection - Battery Management System prevents accidents by managing battery charge status, cell, balancing and various other fine-tuning. If an abnormality is detected in the battery, the battery is automatically controlled (on/off) through a relay (a device that operates under certain conditions to open/close circuits).

Manual Protection - A fuse is designed to shut off currents if a short circuit is detected in the car or the battery.

It is no surprise that there are concerns about electrocution while charging the battery. However, EVs are safe even charging outdoors on the rainiest days, due to the charging port design that prevents water inflow, and various shock prevention mechanisms and steps. First of all, a drain hole within the charging port dispels moisture inflow due to precipitation conditions, preventing electric shock. Once the charging gun and port are connected, a seal prevents any further inflow of liquid. And just in case, pressing the charging gun button to cease charging immediately stops the electric flow, preventing any damage to connector contact points. Another shock prevention measure waits for a complete connection between the vehicle and the charger before allowing a current to flow.